The Stand-Off MPV Bracket in code compliance is used for attaching cladding systems to buildings. This blog and video review the development of the bracket, in compliance with the NFPA 285 code, installation, and examples of the bracket in use. Our video goes into more detail with many examples of projects.

Key moments in the video include

- Rainscreen Attachment System (video 1:06)

- The Stand-Off MPV Bracket (video 10:55)

- Does Our Product Pass NFPA 285? (video 18:47)

- Standard Sizes (video 20:24)

- Why Zinc and Yellow Chromate Plating? (video 20:54)

- The Galvanizing Process (video 21:34)

- Projects (video 21:34) showing different methods of installation with the Stand-Off MPV Bracket.

Continuous installation requirements have been in the International Energy Code since 2009.

The 2015 version of the code included a definition of continuous insulation. Many people in the industry are using their interpretation of the term.

The continuous insulation requirement intends to minimize thermal bridging through the insulation. Thermal Bridges reduce the effectiveness of the insulation.

The definition made the use of continuous z-faring for the attachment of cladding systems, a violation of the code.

Several companies have developed products and assemblies to comply with the code requirements.

We looked at them and we didn’t like any of them as they all fell short, some more than others, so we invented our own… the Stand-Off MPV Bracket.

The first thing we did was make a list of all the requirements for the cladding attachment system that we think are necessary.

The Rainscreen Attachment System Requirements (1:06)

- Can withstand the loads imposed upon it.

- Comply with IBC and IECC requirements.

- Doesn’t burn (non-combustible construction types)

- Result in minimal thermal bridging through the continuous insulation

- Install easily with few parts to assemble

- Provides the required adjustability without having to shim.

- Reasonable cost

- Does not require cutting and fitting of the continuous insulation.

- Provides for the mechanical fastening of the continuous insulation

Typically, this is done with thousands of screws or fasteners which pass through the continuous insulation creating thermal bridges.

This creates thousands of holes through your air, water, and vapor barrier.

There are non-combustibility requirements and fire reading requirements for load-bearing members and other components and exterior wall assemblies in the IBC.

Chapter 6 deals with this.

Please refer to our video where we review construction types 1- 5 for non-combustible materials, fire rating requirements of load-bearing structures, and exterior wall fire rating requirements.

Thermal Bridging (7:58)

Thermal bridging through the continuous insulation needs to be dealt with in order to comply with the performance requirements of the International Energy Code.

The IECC deals with the thermal bridging of light gauge metal framing with insulation in table c402.1.4.2.

In the code, the effect of thermal bridging created by continuous Ephron can be both visualized and calculated by using a computer simulation program called therm which can be downloaded for free from the Lawrence Berkeley Laboratories.

The fastening of the continuous insulation layer can result in thousands of penetrations through the air, water, and vapor barrier.

On top of the thousands of holes through the air water and Vapor Barrier, these fasteners are expensive to buy and require a lot of labor to install.

The layout is critical to hit the studs with the fastener so that unfilled holes do not result in the air, water, and vapor barrier.

It also represents thousands of thermal Bridges through continuous Insulation.

So here’s what we came up with (invention).

The Stand-off MPV Bracket (10:56)

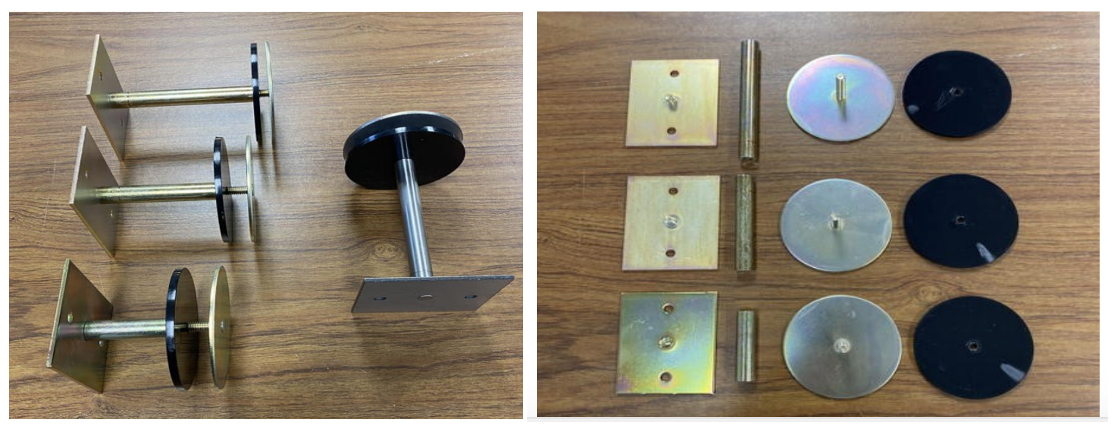

The Stand-Off MPV Bracket is comprised of a base plate, a threaded coupling, a 3” diameter insulation retainer, a threaded rod, and a 12 gauge flat plate. It comes assembled.

Advantages of the Stand-Off MPV Bracket, there are several

- It’s very low thermal bridging

- It is adjustable.

- It doesn’t burn

- Has very few parts

- Easy to install

- Cost-effective

- Seals at the Fasteners

- Mechanically fastens to the continuous insulation

- Does NOT require cutting and fitting of the insulation

They have a rubber gasket on them and compressing the plate against the air, water and Vapor Barrier turns the air water, and Vapor Barrier into a gasket around the screw penetrations.

This mechanically fastens The Continuous insulation, so it doesn’t require cutting and fitting the insulation around the bracket.

Disadvantages of the Stand-Off MPV Bracket

We have not had any issues or complaints with the hundreds of thousands of brackets we’ve sold to date and the many on projects in which they are used.

NFPA 285 (18:47) Code Compliance

We often get asked if our product passes NFPA 285.

NFPA 285 is the Standard Fire Test Method for the Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, which provides a consensus process for determining the flame-spread resistant properties of these materials when exposed to interior fires.

This is an assembly test, not a product or material test.

The Standoff MPV Bracket in code compliance is made from metal so we do not feel that it would add to the fire propagation or heat generated in such a test.

We requested an opinion letter from the person who wrote NFPA 285 – Chest Bidal and received this letter for the low price of $5,000.

He says that including the Stand-Off MPV Bracket in the NFPA 285 tested assembly would not affect the results of the test.

The Stand-Off MPV Bracket uses hat furring as the attachment rail

This is the most typical installation of the Stand-Off MPV Bracket and uses hat furring as the attachment rail for the cladding system.

We have seen many z-faring used on a project which we thought was odd as the mini z-furing has to be a much lower gauge of Steel than the Hat firing due to The Eccentric load that it has to bear.

We asked the contractor why they used it. They told us that their structural engineer felt that using these is more comfortable. The Z-faring flat sock can also be used as the attachment rail. It will also have to be fabricated from much lower gauge steel as it is not as strong as the firing made from the same gauge steel. This system was used in our first project, which is a hospital.

Additionally, in Virginia which has a zero lot link lot line restriction they wanted to maximize the interior square footage of the building by making the exterior wall thinner.

The Stand-Off MPV Bracket is offered in Standard Sizes (20:24),

1 1/2″, 2“, 3”, 4”, and 6” Insulation.

Custom sizes are available though we have made brackets for

- three and a half inches of insulation,

- five-inch insulation and

- eight-inch continuous insulation.

The finishes that we offer for our Stand-Off MPV Bracket are zinc and yellow chromate plating and stainless steel.

Why Zinc and Yellow Chromate Plating? (20:54)

Why did we use zinc and yellow chromate plating for our protection?

Well, the bracket couldn’t be hot tip galvanized due to the threads the components wouldn’t thread together with the hot dip galvanizing plating.

We didn’t want to stamp the bracket components out of the galvanized sheet since the edges of the components would not be adequately protected.

In our opinion, ceramic coatings made the bracket more expensive than stainless steel so we found zinc and yellow chromate plating offered the closest protection to hot dip galvanizing. This is pretty much the industry standard for components exposed to the elements in the exterior wall.

The Galvanizing Process (21:34)

Looking at the galvanizing process options…

There’s Batch Hot Dip Galvanizing, which we found wouldn’t work with our bracket.

There’s Continuous Sheet Galvanizing. Again, our concern is of cutting or stamping the components out of a continuous sheet.

Zinc Painting requires the components all to be hung up and spray painted. And that was very labor intensive.

Zinc Spray Metallizing has the same effect as the zinc plating it would take a lot of Labor to hang those up and spray.

And then there’s Mechanical Plating which we do not feel offers as good protection as Hot Dip Galvanizing.

There’s electroplate galvanizing. We didn’t feel was as good as the hot dip galvanizing.

And finally, there’s Zinc Plating, which we use as it is the most cost-effective plating.

See the video for further discussion of the corrosion resistance, ASTM Standard Specifications, and Zinc and Chromate plating.

Projects using the Stand-Off MPV Bracket

In the video, I discuss over ten different projects (28:17) where EXO-TEC’s Stand-Off MPV Bracket is installed and some of the differences and similarities that speak to all of the requirements discussed previously in this writing.

The first is one project where our Stand-Off MPV Brackets are used with two-pound density closed-cell spray foam for continuous insulation.

The base plates were installed and then the spray foam was applied around them.

In the next project, you will see the spray foam installed in the top plates of the Stand-Off MPV Bracket. Also, the hat furring is partially installed.

A third picture of the same job shows all the Hat firing installed in the vertical orientation and here the siding was fiber cement clapboard siding being installed on the project.

Please refer to the video at 28:17 for a discussion of additional projects showing you different methods of installation with the Stand-Off MPV Bracket.

Conclusion

In summary, in this blog, we highlight the development of the Stand-Off MPV bracket as a trusted Rainscreen Attachment system, the NFPA 285 code compliance, installation, standard sizes, plating options, the galvanizing process, and examples of the bracket in use.

Please watch the video for close-up details of our projects.

If you have any questions, please feel free to submit them to me via email Len@exo-tec.biz. If there is any data you want we have all the test reports available on our website.

You can Request Samples through our website as well.

We look forward to serving you.

Len Anastasi has been working in the construction industry for over 30 years in masonry, waterproofing and restoration work.

He currently owns EXO-TEC Manufacturing, Inc., EXO-TEC Solutions, Inc. and EXO-TEC Consulting, Inc.

In his construction and consulting work, he has performed inspections and repairs on over 300 buildings.

Len has given expert testimony in trials and reviews on dozens of legal cases.

He is a member of ASTM’s E 06 Committee, the Boston Society of Architects Building Enclosure Council, Air Barrier Association of America, the Construction Specifications Institute, and the International Concrete Repair Institute.

Book Len for your Next Event!

Len Anastasi has been working in the construction industry for over 30 years in masonry, waterproofing and restoration work.

He currently owns EXO-TEC Manufacturing, Inc., EXO-TEC Solutions, Inc. and EXO-TEC Consulting, Inc.

In his construction and consulting work, he has performed inspections and repairs on over 300 buildings.

Len has given expert testimony in trials and reviews on dozens of legal cases.

He is a member of ASTM’s E 06 Committee, the Boston Society of Architects Building Enclosure Council, Air Barrier Association of America, the Construction Specifications Institute, and the International Concrete Repair Institute.

Book Len for your Next Event!